TOX® PRESSOTECHNIK is expanding its range of standard presses: The TOX® FlexPress Compact not only enables flexible tool replacement, but also monitors the process and creates analyses on this basis. Furthermore, the mechanical engineering company from Baden-Württemberg is also establishing a completely reworked press design with this new development.

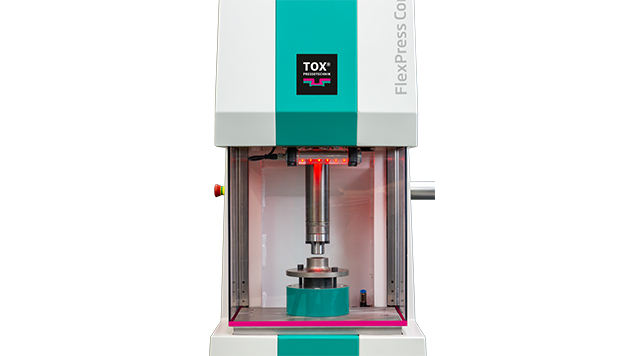

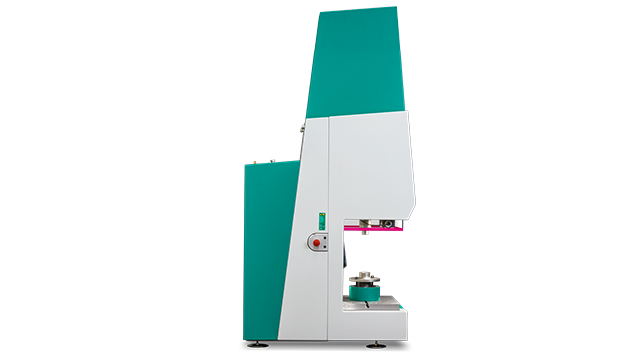

With the TOX® FlexPress Compact, the mechanical engineering company from Weingarten in Germany has developed a new standard press, which keeps an eye on the parameters itself. Not only the concept is new, but also the design. For the first time, TOX® PRESSOTECHNIK is moving away from its known look, without completely eliminating it. In addition to the now dominating color white, touches of green and magenta also uniquely identify the new standard press as having been built by TOX® PRESSOTECHNIK, but lend it a more modern appearance at the same time.

The compact manual workstation only takes up a footprint of 425 x 703 millimeters on a table. With the highly intuitive control, the user can create a new process with just a few clicks via the 13-inch UDI Panel (Universal Data Interface). This is important, as the standard press is flexible in terms of technology – its tools can quickly be changed for any technologies mastered by TOX®, such as clinching, riveting or pressing in. For the first time, TOX® PRESSOTECHNIK has integrated the control cabinet into the press housing, thus reducing the space requirement of the table press.

Quiet power in four designs

The electromechanical drive TOX® ElectricPowerDrive is positioned below a noise-reducing cover and drives the press with 5, 10, 30 or 60 kilonewton depending on the version. The integrated sensors measure each process and transfer the data to the process monitoring. It evaluates the information, creates analyses and thus ensures traceability of each component. Safe operation is ensured by a quiet- and quick-acting electrical safety door – with a touch of magenta – as well as RGBW illumination of the work area: This lights up in red for failed parts and green if everything is in order.

The new TOX® FlexPress Compact with its integrated sensors and flexibility is ideally suited to applications requiring precision and tasks with small parts in small or serial assemblies. In short: Whenever changing components require replacement of tools and users want to record process and quality data seamlessly.